I should have done this from the beginning, but better late than never, I hope.

As many of you have seen in my posts of the past years, I've been workiong on a 65 fastback. It was pretty rusty and "only" a straight 6. Why should it be saved? Well it's kind of a family heirloom.

![Image]()

Here is the video the above was taken from, I'm the little one in the cap.

This car was purchased new for my mother by my father in 1965. It has been in the family all this time. I went over the car in 1979-81, and did the best I could with it as a 16-18 year old with no garage, or prior automotive experience. Most of the major work was farmed out, including the engine rebuild and the paint. I did the complete interior myself, with direction from my late grandfather, who was an experienced upholsterer. I still have the hog ring pliers he gave me, and I intend to use them again...

The car after the first "restoration" in the same spot, but shot from a different angle in 1981.

![Image]()

The car was never in a garage until I took it to my first house in 1992, when it was towed there, It had not moved since 1987. It was in pretty bad shape.

I moved to my new house in 1999. Many of the choices made on the house were related to the old 65 and the automotive interests it spawned. Basically I bought a garage with a house attached.

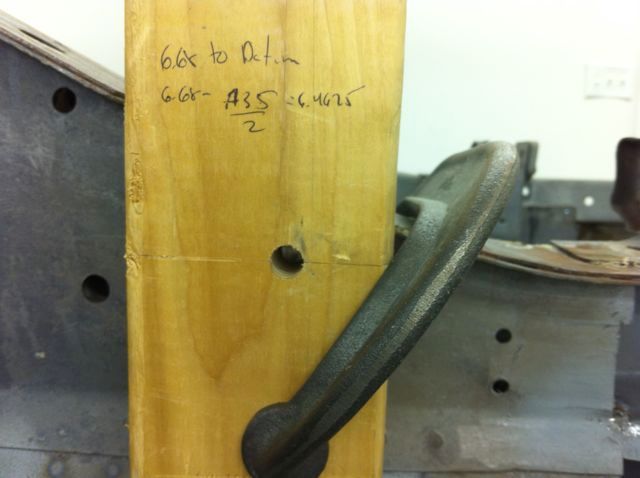

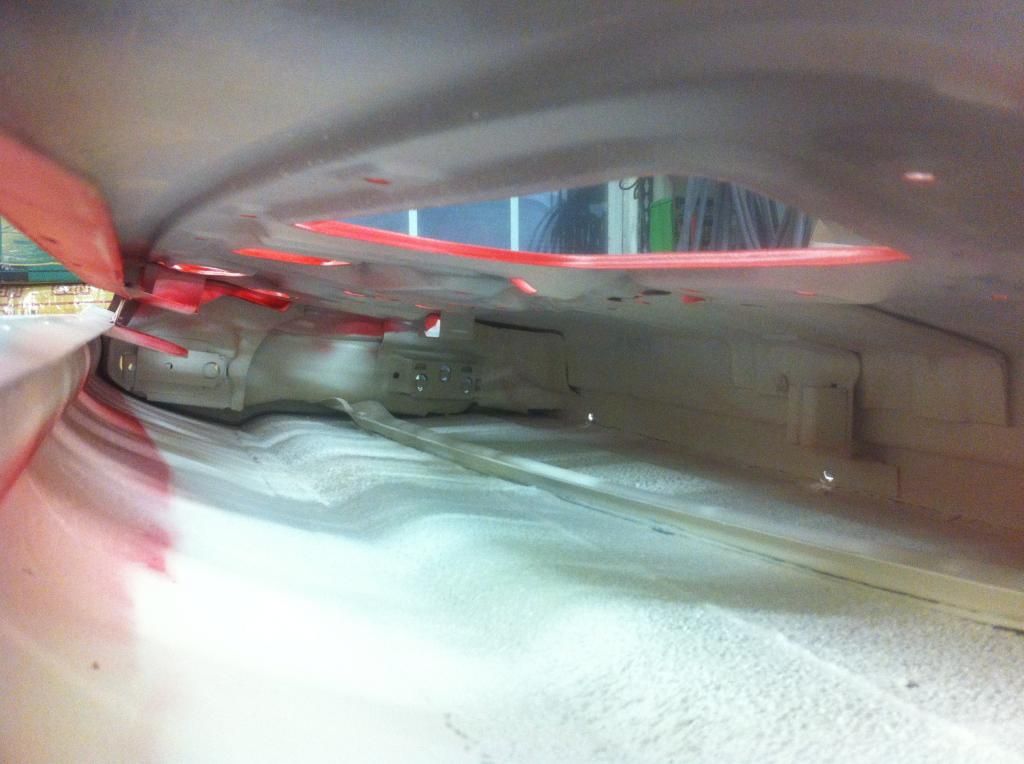

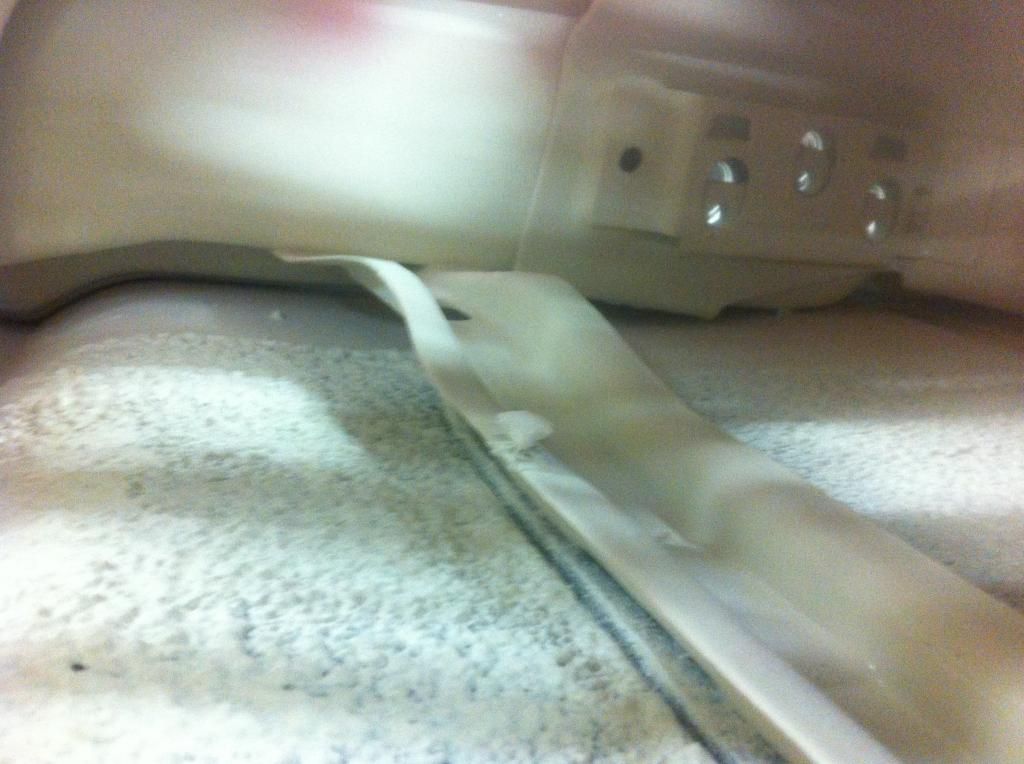

It took from October of 1999 until spring 2001 to get the garage ready for the restoration. I had a direct vent gas heater installed. I installed 16 2 bulb 4ft flourescent fixtures. I wanted to see what I was doing. The lights took 250 feet of wire to hook up ! I installed other little things like an 80 gallon vertical tank compressor, a hose bib( water), lots of air outlets, had the garage painted etc. I moved the car into position on Mothers day 2001 and started work.

![Image]()

![Image]()

![Image]()

![Image]()

![Image]()

![Image]()

![Image]()

![Image]()

![Image]()

![Image]()

![Image]()

![Image]()

More to come...

As many of you have seen in my posts of the past years, I've been workiong on a 65 fastback. It was pretty rusty and "only" a straight 6. Why should it be saved? Well it's kind of a family heirloom.

Here is the video the above was taken from, I'm the little one in the cap.

This car was purchased new for my mother by my father in 1965. It has been in the family all this time. I went over the car in 1979-81, and did the best I could with it as a 16-18 year old with no garage, or prior automotive experience. Most of the major work was farmed out, including the engine rebuild and the paint. I did the complete interior myself, with direction from my late grandfather, who was an experienced upholsterer. I still have the hog ring pliers he gave me, and I intend to use them again...

The car after the first "restoration" in the same spot, but shot from a different angle in 1981.

The car was never in a garage until I took it to my first house in 1992, when it was towed there, It had not moved since 1987. It was in pretty bad shape.

I moved to my new house in 1999. Many of the choices made on the house were related to the old 65 and the automotive interests it spawned. Basically I bought a garage with a house attached.

It took from October of 1999 until spring 2001 to get the garage ready for the restoration. I had a direct vent gas heater installed. I installed 16 2 bulb 4ft flourescent fixtures. I wanted to see what I was doing. The lights took 250 feet of wire to hook up ! I installed other little things like an 80 gallon vertical tank compressor, a hose bib( water), lots of air outlets, had the garage painted etc. I moved the car into position on Mothers day 2001 and started work.

More to come...