$200 Disk Brakes anyone?

First I would like to clarify that I cannot and will not take credit for this. I first read an article on Ford Muscle by my buddy F15Falcon. Here is his tech article.

Cheap Big Disc Brakes For Mustang/ Falcon - FordMuscle.com Forums

I did stray from his plans a bit but not much. I will do a complete write up once I finish so I will just outline plans for now. Here is my progress so far.

I will finish with 11.5” disk brakes for about $200 when all is said and done.

![Image]()

![Image]()

I started out with big bore GM calipers. I know GM parts on a Mustang is a deadly sin, but at $12 a pop with lifetime warranty, they are hard to beat. They have a 2-15/16” piston and come with caliper bolts.

![Image]()

![Image]()

![Image]()

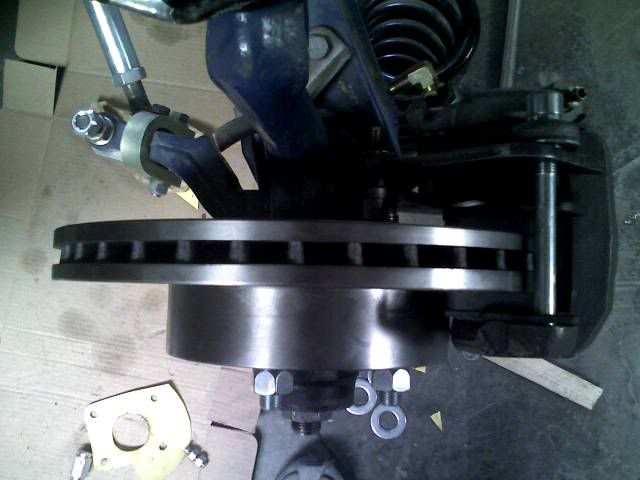

I chose to re-use my stock drum hubs and try to use bigger rotors both in diameter and thickness. I pressed the hubs out of the drums, and studs out of the hubs which was no easy task. I then mounted the hubs back on the spindle for some measurements.

![Image]()

I originally had planned to use Wilwood hats and rotors for desired rotor offset but they were $80 per hat and $30 per rotor and that would have killed my budget.

I found the sweet spot at about 1.5” of offset. I didn’t want the caliper too far back or out so it would not interfere with either the wheel or the sway bar.

![Image]()

I figured there had to be a factory rotor that would fit my needs. My first try was a 97 Mustang but there was too little offset. My next try was a 95 Crown Victoria front rotor and I nailed it on the head!!! 11.5” diameter, about 1.5” of offset, 1” thick just like the GM rotors, and a 4.5” bolt pattern. They run about $35 a piece.

![Image]()

![Image]()

These rotors will require a little bit of work to make sure they are centered on the hub, but that will be easy and won’t cost hardly anything. Next, I will be ordering caliper bracket from Speedway Motors for $10 a piece, some fittings, and stainless steel braided hoses.

Brackets

![Image]()

Fittings

![Image]()

Hoses

![Image]()

So the tally:

1975 Chevy Impala Calipers: $12/each assuming you provide cores. $24

1975 Chevy Impala Brake Pads: $20 w/ lifetime warranty

1995 Crown Victoria Front Rotors: $35 each. $70

Speedway Motors Big GM Caliper Brackets: $10/each. $20

Speedway Motors Fittings: $8/each. $16

Speedway Motors Stainless Braided Hoses: $11/each. $22

Total so far: $172 plus I will still need some bolts and spacers which shouldn’t be more than $25.

Hoping to get more done on this in the coming days but with the holidays and shipping, it’ll be more like 2-3 weeks before I can get this done.

Fred

First I would like to clarify that I cannot and will not take credit for this. I first read an article on Ford Muscle by my buddy F15Falcon. Here is his tech article.

Cheap Big Disc Brakes For Mustang/ Falcon - FordMuscle.com Forums

I did stray from his plans a bit but not much. I will do a complete write up once I finish so I will just outline plans for now. Here is my progress so far.

I will finish with 11.5” disk brakes for about $200 when all is said and done.

I started out with big bore GM calipers. I know GM parts on a Mustang is a deadly sin, but at $12 a pop with lifetime warranty, they are hard to beat. They have a 2-15/16” piston and come with caliper bolts.

I chose to re-use my stock drum hubs and try to use bigger rotors both in diameter and thickness. I pressed the hubs out of the drums, and studs out of the hubs which was no easy task. I then mounted the hubs back on the spindle for some measurements.

I originally had planned to use Wilwood hats and rotors for desired rotor offset but they were $80 per hat and $30 per rotor and that would have killed my budget.

I found the sweet spot at about 1.5” of offset. I didn’t want the caliper too far back or out so it would not interfere with either the wheel or the sway bar.

I figured there had to be a factory rotor that would fit my needs. My first try was a 97 Mustang but there was too little offset. My next try was a 95 Crown Victoria front rotor and I nailed it on the head!!! 11.5” diameter, about 1.5” of offset, 1” thick just like the GM rotors, and a 4.5” bolt pattern. They run about $35 a piece.

These rotors will require a little bit of work to make sure they are centered on the hub, but that will be easy and won’t cost hardly anything. Next, I will be ordering caliper bracket from Speedway Motors for $10 a piece, some fittings, and stainless steel braided hoses.

Brackets

Fittings

Hoses

So the tally:

1975 Chevy Impala Calipers: $12/each assuming you provide cores. $24

1975 Chevy Impala Brake Pads: $20 w/ lifetime warranty

1995 Crown Victoria Front Rotors: $35 each. $70

Speedway Motors Big GM Caliper Brackets: $10/each. $20

Speedway Motors Fittings: $8/each. $16

Speedway Motors Stainless Braided Hoses: $11/each. $22

Total so far: $172 plus I will still need some bolts and spacers which shouldn’t be more than $25.

Hoping to get more done on this in the coming days but with the holidays and shipping, it’ll be more like 2-3 weeks before I can get this done.

Fred