To start, I had been looking for a 65/6 fb to build for several months when I bought a 66 coupe. The coupe was disassembled when I bought it. I made a restomod of it. Literally, the week I registered the coupe for street use I found a 65 fb in Albequerque. The car was advertised for $5k and seller would not show it until that saturday at noon. This was a wednesday in mid december. I offered him $100 to show me the car first, his to keep whether I bought the car or not.

He agreed and I made the purchase.

The story on the car goes like this:

-C code car

-Same owner since 69-it came with the 69 New Jersey title

-the owner was a drag race guy

-In 1975 was towed out to Albequerque with a U-haul truck using a single axle dolly

-the car blew the left rear tire on the trip and took out the quarter panel

-the car was partially disassembled for paint and some panel replacement and parked ever since

That's how I found the car. I did not take any pictures of it. Suffice it say it was 6 different colors not including the shades of rust.

The good:

It was 5k

all the interior was there

glass is good

close ratio toploader

289 engine with a claimed 300hp and hi po heads

vintage cast iron scattershield

new stock rad

new mallory billet dual point dist

the bad:

needs floor pan halves

left quarter

trunk floors, rad support, front right apron and taillight panel marginal but getting replaced

dent in left front subframe where it angles up

dents in rocker panel

fenders will need work or replacement

8" rear end cracked and teeth missing from ring gear

the goofy:

coil spring shocks all the way around

leaf spring shackles a foot long (I think he was going for the gasser look)

I took the car apart in January. Initially, I was going to sell the coupe to finance this but my wife laid claim to the coupe. So, I am progressing as money allows.

So far, I have completed the following:

-media blast the areas under the car to repair

-pulled out dent in front subframe

-pulled out dents in rocker

-replaced rad support and right front apron

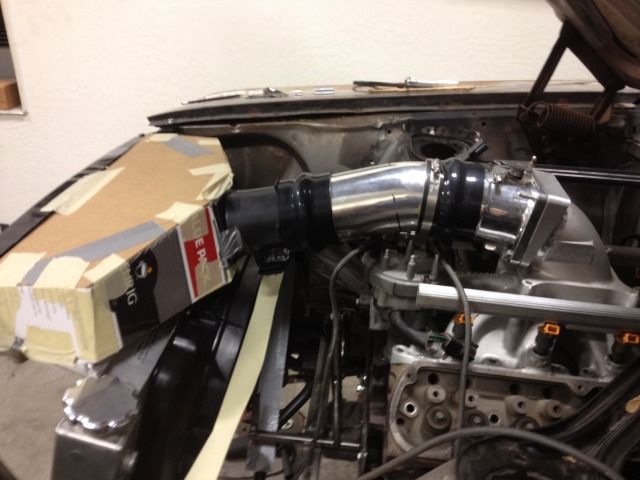

-welded up a bunch of the sheet metal and engine compartment

-found/bought the brakes and wheels (cobra brakes and boss 338 wheels)

-T5z waiting patiently

-9" rear with traction device and 3.89's

-driver side floor replaced

-driver side subframe connected

Pictures to follow.

Yes, I know I should have taken pictures of it on the trailer. But, my wife gave me so much caca after I brought it home. She would have mocked me more if I busted out the camera. Even my kids were getting in on the ribbing.

He agreed and I made the purchase.

The story on the car goes like this:

-C code car

-Same owner since 69-it came with the 69 New Jersey title

-the owner was a drag race guy

-In 1975 was towed out to Albequerque with a U-haul truck using a single axle dolly

-the car blew the left rear tire on the trip and took out the quarter panel

-the car was partially disassembled for paint and some panel replacement and parked ever since

That's how I found the car. I did not take any pictures of it. Suffice it say it was 6 different colors not including the shades of rust.

The good:

It was 5k

all the interior was there

glass is good

close ratio toploader

289 engine with a claimed 300hp and hi po heads

vintage cast iron scattershield

new stock rad

new mallory billet dual point dist

the bad:

needs floor pan halves

left quarter

trunk floors, rad support, front right apron and taillight panel marginal but getting replaced

dent in left front subframe where it angles up

dents in rocker panel

fenders will need work or replacement

8" rear end cracked and teeth missing from ring gear

the goofy:

coil spring shocks all the way around

leaf spring shackles a foot long (I think he was going for the gasser look)

I took the car apart in January. Initially, I was going to sell the coupe to finance this but my wife laid claim to the coupe. So, I am progressing as money allows.

So far, I have completed the following:

-media blast the areas under the car to repair

-pulled out dent in front subframe

-pulled out dents in rocker

-replaced rad support and right front apron

-welded up a bunch of the sheet metal and engine compartment

-found/bought the brakes and wheels (cobra brakes and boss 338 wheels)

-T5z waiting patiently

-9" rear with traction device and 3.89's

-driver side floor replaced

-driver side subframe connected

Pictures to follow.

Yes, I know I should have taken pictures of it on the trailer. But, my wife gave me so much caca after I brought it home. She would have mocked me more if I busted out the camera. Even my kids were getting in on the ribbing.