The only gauge that appears to work currently is the temp gauge. The fuel sender is new, and I've checked the resistance on it and the temp and oil pressure senders. All those seem right.

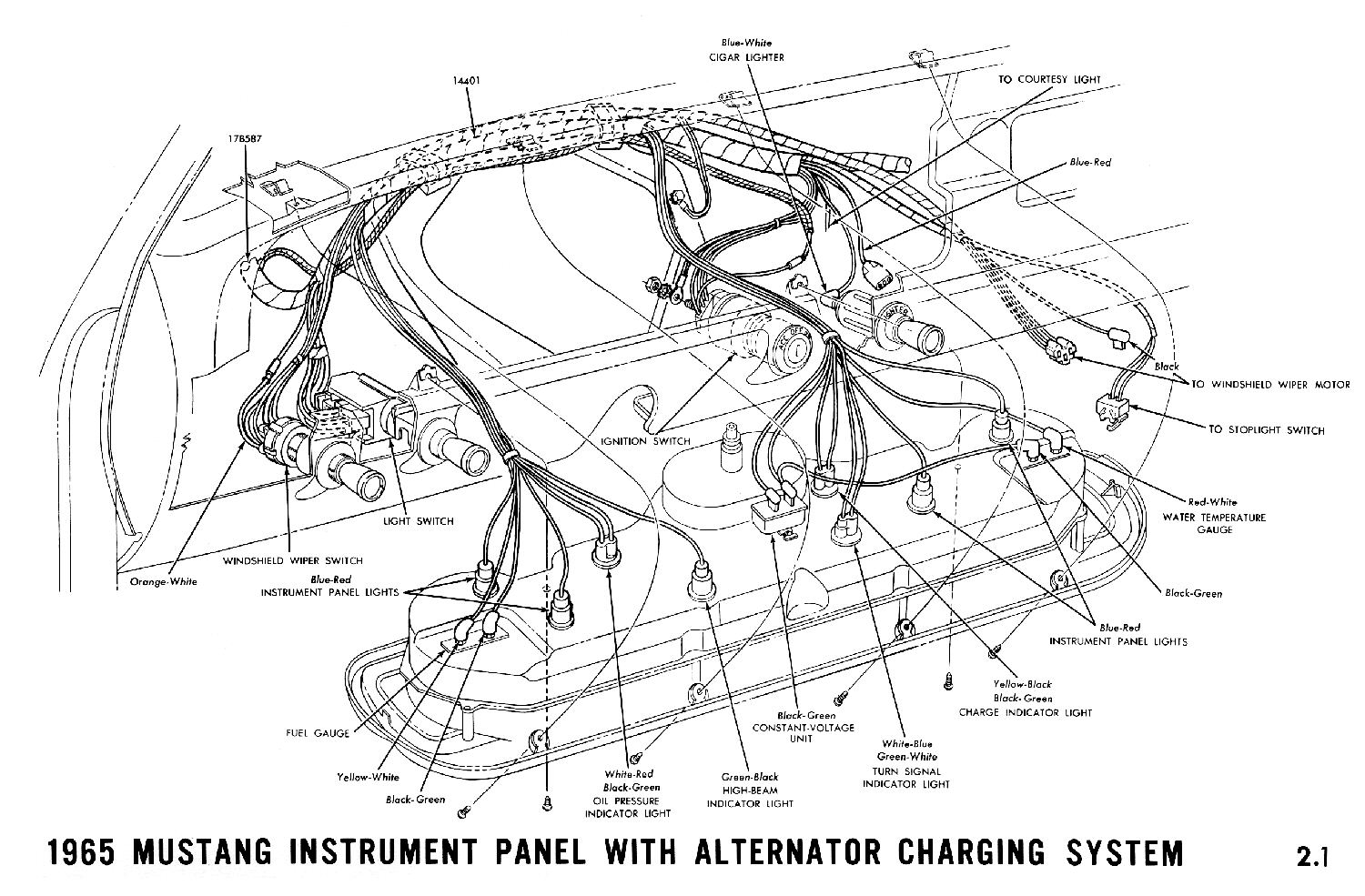

Last night, I puller the dash cluster out and started checking various points. On the CVR, the ground lug shows continuity to other ground points on the car, and I get 12.5 VDC to the ignition lug. I wasn't getting anything on the CVR output lug with my DMM, so I tried an analog one and got signal. It was only showing around 1.5 - 2.5 VDC on the sweep. I think there's some dampening in that MM as well, so I'm thinking the "1.5" should actually be 0, making the "2.5" closer to 4 - still a little lower than I gather it is supposed to be.

My question: do these CVRs ever wear out by giving a low output? My (limited) experience with other CVRs is that they either fail at open or close, not low output.

If it sounds like my CVR is probably OK, I think I'm going to pull the whole cluster and power/resist the individual gauges on a breadboard. Assuming I have + voltage to the + lug on each gauge, and reasonable resistance to ground from each sender wire, if the gauge doesn't work, it has to be a problem with the actual gauge, right?

Last night, I puller the dash cluster out and started checking various points. On the CVR, the ground lug shows continuity to other ground points on the car, and I get 12.5 VDC to the ignition lug. I wasn't getting anything on the CVR output lug with my DMM, so I tried an analog one and got signal. It was only showing around 1.5 - 2.5 VDC on the sweep. I think there's some dampening in that MM as well, so I'm thinking the "1.5" should actually be 0, making the "2.5" closer to 4 - still a little lower than I gather it is supposed to be.

My question: do these CVRs ever wear out by giving a low output? My (limited) experience with other CVRs is that they either fail at open or close, not low output.

If it sounds like my CVR is probably OK, I think I'm going to pull the whole cluster and power/resist the individual gauges on a breadboard. Assuming I have + voltage to the + lug on each gauge, and reasonable resistance to ground from each sender wire, if the gauge doesn't work, it has to be a problem with the actual gauge, right?