I am super fired up and pissed right now....

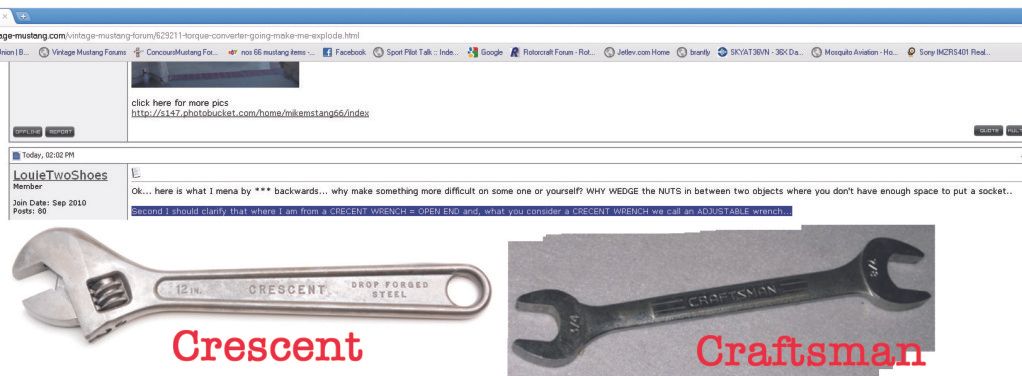

The torque converter is attached to the flexplate *** back words via four bolts... The nuts that you cna only get to are wedged in between the flexpate and inspection cover. Whose bright idea was this? I have stripped 2 of 4 bolts trying to get them to un screw using a 9/16 crecent wrench and a hammer and no hammer...I am tired, hungry, late for work and pissed off..... There is no room to get a box wrench in there, no room for a socket or ratchet to get in there.. only the crecent wrench... there ahs to be a better and easier way to do thid before I beat this engine to death...... the other thing is.. the damn header BOLTS are WAAAAAyYYYYYYY to close to the pipes on the headers... what gives here? I have two size bolts here.. a 7/16 and a 3/8s... what the frig? Any ideas here? I am 5 seconds from going ape S***...

-Louie

The torque converter is attached to the flexplate *** back words via four bolts... The nuts that you cna only get to are wedged in between the flexpate and inspection cover. Whose bright idea was this? I have stripped 2 of 4 bolts trying to get them to un screw using a 9/16 crecent wrench and a hammer and no hammer...I am tired, hungry, late for work and pissed off..... There is no room to get a box wrench in there, no room for a socket or ratchet to get in there.. only the crecent wrench... there ahs to be a better and easier way to do thid before I beat this engine to death...... the other thing is.. the damn header BOLTS are WAAAAAyYYYYYYY to close to the pipes on the headers... what gives here? I have two size bolts here.. a 7/16 and a 3/8s... what the frig? Any ideas here? I am 5 seconds from going ape S***...

-Louie