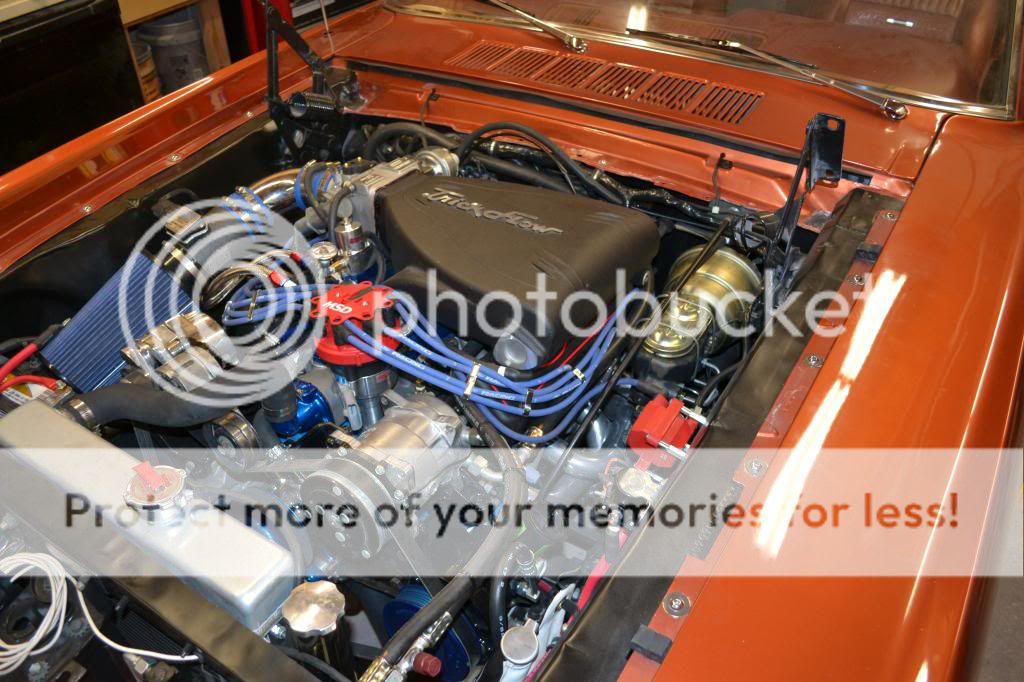

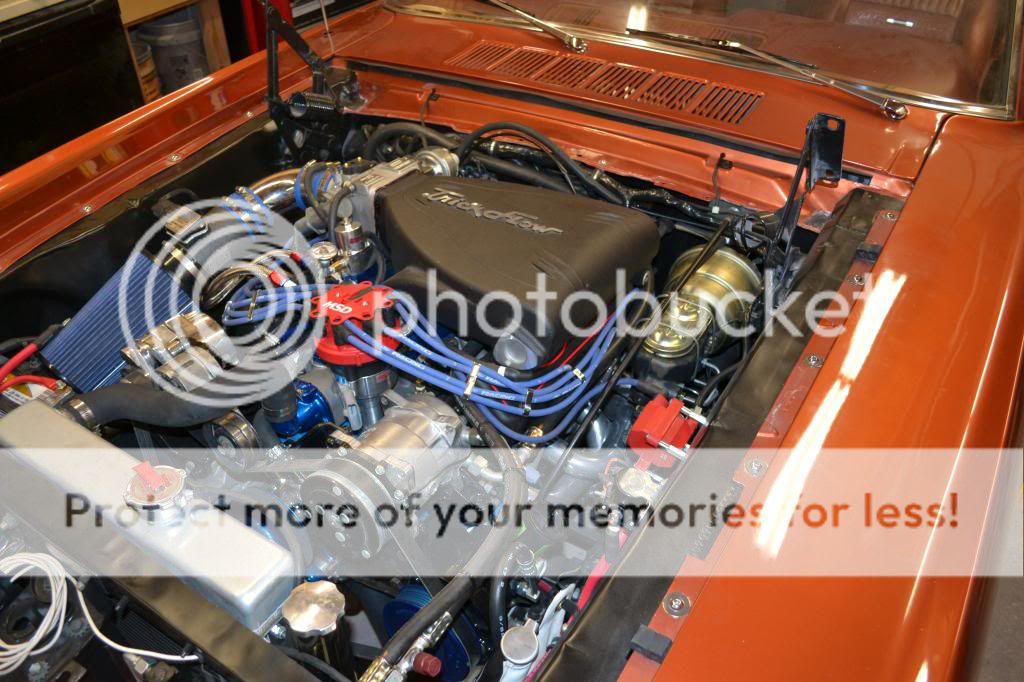

I think I have finally finished the installation of my 5.0 EFI engine conversion. It's been a long time in the making, but it's finally there. I'm hoping to have it running by the end of this weekend. I am so ready to drive this thing!

It's basically a complete Trick Flow package that should make around 350 HP. Overall it fits very well. I had to cut a few inches off the intake elbow so that the air filter would clear the battery. All I need to do now is put some gas in it, purge the air from the fuel lines, connect up the engine computer, and see if it will start. I am also doing something a little different here - I know everyone usually dumps the emissions control equipment since it's not required on a car this old, but I've got it all hooked up.

It's basically a complete Trick Flow package that should make around 350 HP. Overall it fits very well. I had to cut a few inches off the intake elbow so that the air filter would clear the battery. All I need to do now is put some gas in it, purge the air from the fuel lines, connect up the engine computer, and see if it will start. I am also doing something a little different here - I know everyone usually dumps the emissions control equipment since it's not required on a car this old, but I've got it all hooked up.